Constrained marking guide provides sharper, more accurate mark

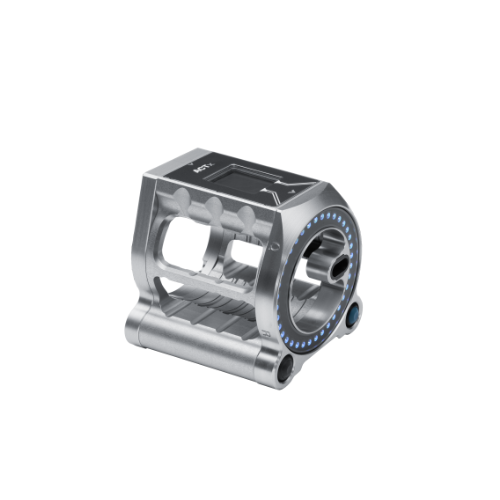

Smaller, lighter tool with enhanced workflow

Orientation jig has 30-day battery life (approx.)

Core sizes: H, H3,N, N3, N2

Automated QA/QC & integrated workflow

High quality, auditable data

Technical specifications

Core Sizes

N, N2 N3, H, H3

Dimensions

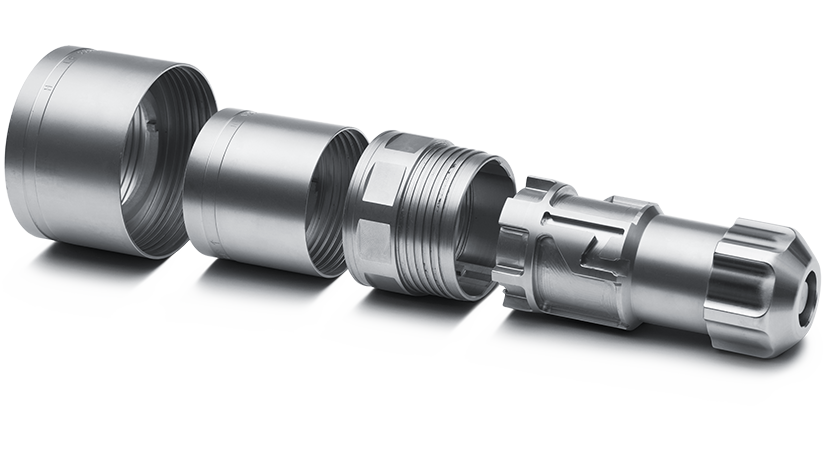

Downhole Unit (without coupling adapter)

Length

109mm

Diameter

48mm

Weight

560 g

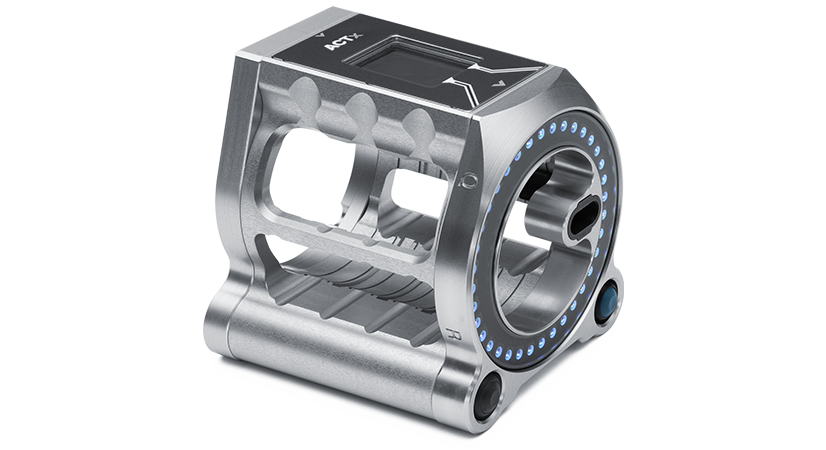

Orientation Jig

Length

120 mm

Width

108 mm

Height

115 mm

Weight

1010 g

Operational environment

Downhole Unit

Operational Temperature

-30°C to 60°C (-22°F to 176°F)

Storage Temperature

-30°C to 60°C (-22°F to 176°F)

Orientation Jig

Operational Temperature

-20°C to 50°C (-4°F to 122°F)

Storage Temperature

-20°C to 50°C (-4°F to 122°F)

Charging Temperature

3°C to 40°C (37°F to 104°F)

Performance

Downhole unit

Dip Range

0° to ± 87°

Accuracy

± 1°

Orientation Jig

Accuracy

± 1°

Battery

Downhole unit

Battery type

Non-rechargeable lithium battery pack

Battery life

1,400 orientations (Approximate)

Orientation Jig

Battery Type

Rechargeable Lithium Ion

Charge Time

9 hours

Battery Life

30 days (Approximate)

Product support, anywhere, anytime

We’re committed to offering the highest level of support to our customers, which is why we have launched our Customer Care Portal, so you can receive support on our products and solutions, wherever you are in the world.

- Raise product support requests anytime (24/7)

- Access our comprehensive knowledge base

- Track and manage your support requests

Control multiple survey tools such as the REFLEX EZ-GAMMA™, REFLEX GYRO SPRINT-IQ™ and REFLEX EZ-GYRO™ through one app.

Less wire, less charges, less equipment

Using one tablet and interface with multiple tools at the same time reduces hardware costs (including tablets, and chargers) while increasing functionality. You can now monitor everything from the one app.

Boost productivity

IMDEX SURVEY-IQ™ has crossed the threshold in saving hours for drilling operations by increasing productivity up to four times compared to using conventional apps.

Multi tool, multi stream, real-time information

IMDEX SURVEY-IQ allows efficient and simultaneous quality assured survey and gamma logging that can be completed by one member of the drill crew. Survey results are immediately available for approval via the cloud-based service HUB-IQ. As well as further analysis in ioGAS™ or 3D visualisation software such as Seequent Central.

Time stamped drillers run sheet

With paperless run sheets, the driller or supervisor has the ability to work out how many meters per shift, when the drilling happened, and even if there were stops or delays.

Frequently asked questions

What is core orientation?

- Electronic Core Orientation Instruments

- Dipmeter and borehole televiewers

- Structural Geology techniques (field observations, mapping, geophysical methods, and laboratory experiments)

- Photogrammetry

What holes sizes is the ACTx compatible with?

The ACTx can currently be used to orient core in hole sizes H, H3, N, N3, N2.

What if we need to orient core in a P or B hole size?

For P and B hole sizes, the ACTIII tool is the recommended IMDEX core orientation solution.

Why is QA/QC data important in core orientation?

QA/QC data is important in core orientation as it removes the ambiguity of what went wrong if a poor orientation occurs.

.png)

.png)

.png)

.png)

-Product-Carousel.png)