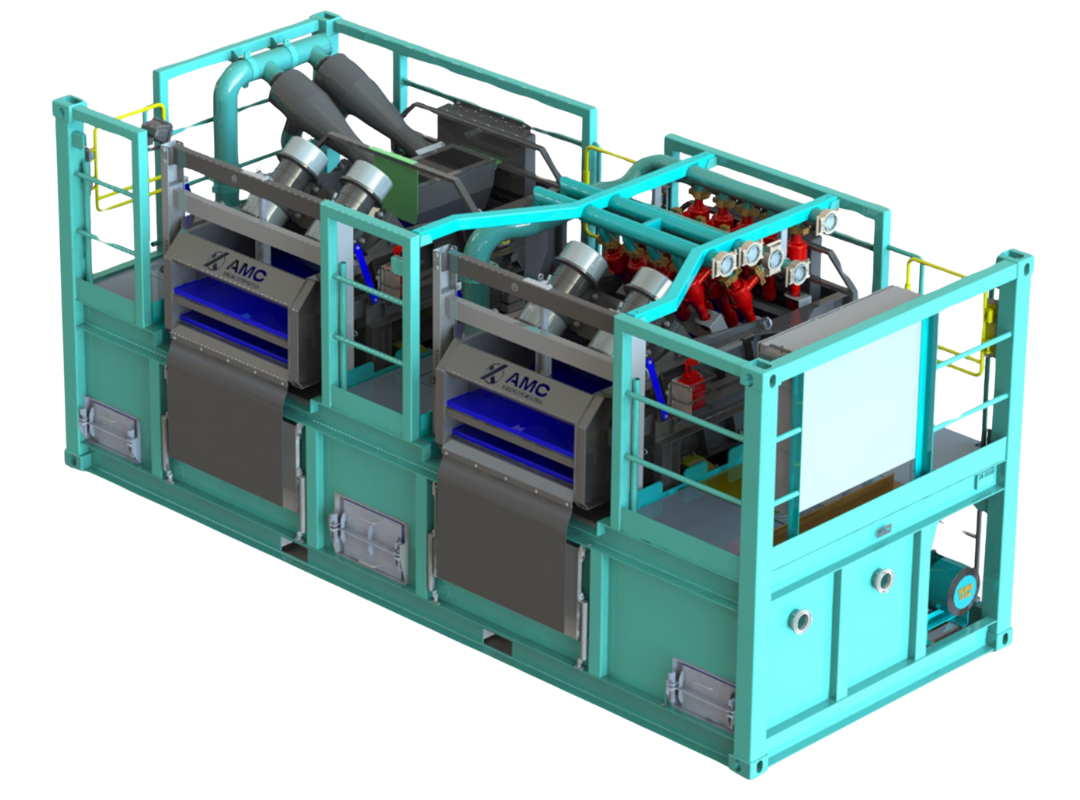

Solids Removal Units

Our technology isn't just about drilling; it's a transformative force, for efficient discovery, streamlined timelines, controlled costs, and unparalleled safety standards.

Elevate your drilling program with a solution that doesn't just meet industry challenges but exceeds them, ensuring a sustainable and productive future for your projects.

Deliver smarter drilling with IMDEX.

Elevate your drilling program with IMDEX

Cost savings

Reduced water usage (>60%), minimising cartage to and from drill site and optimised mud consumption.

Improved HSE

Minimised manual handling – less waste & mud usage. Risk exposure reduced – traffic reduction & sump elimination.

Productivity gains

Improved bit-on-bottom time via clean mud program. Rate of penetration increase with lower percentage of solids in mud system.

Measurable benefits for the environment

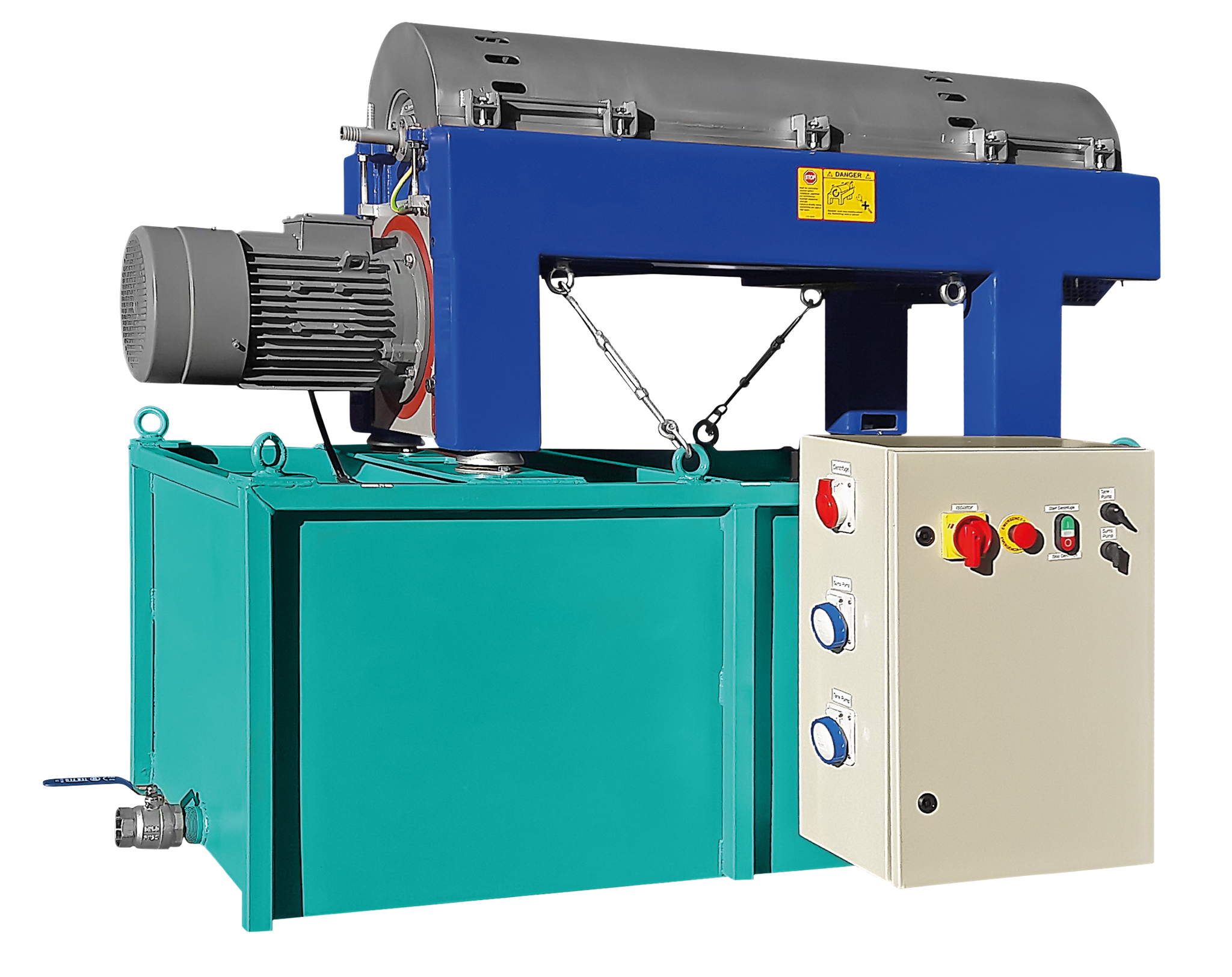

Our award-winning Solids Removal Unit™ is the ultimate companion for drillers, enabling cost-effective, minimal-impact drilling, even in the most restricted locations.

Available in several configurations, these innovative closed-loop systems eliminate the use of sumps and maintain drilling fluid at optimal performance, delivering maximum ROI, and drastic water, mud and waste reductions.

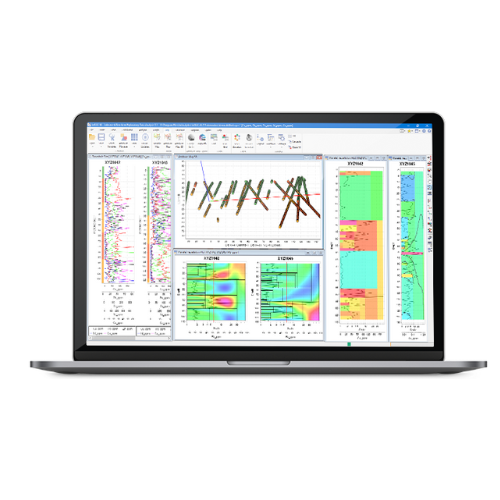

Enhanced drilling productivity

As the cost of drilling increases, the need to improve productivity is paramount. Additional costs caused by higher operational standards, environmental restrictions and increased hole depths will continue.

Our solutions assist you to:

- Hit targets accurately

- Drill with precision and at speed

- Reduce down-time

- Be safe and environmentally responsible

- Deliver cost-effective, quality drilling programs with the data to back them up

Game-changing technology

Our range of innovative equipment is developed to optimise productivity, reduce material consumption and limit environmental impact.

IMDEX XTRACTA™ (in development - coming soon) allows the driller to inspect and/or change the bit/reamer each time the core is retrieved. This means there is no need to pull the rods to change bits and the hole is always cased, maintaining hole integrity.

.png)

.png)

.png)

.png)

.jpg)

_1.png)

.png)