Achieve planned drilling accuracy

Reduce environmental impact

Reduce drilling time and cost

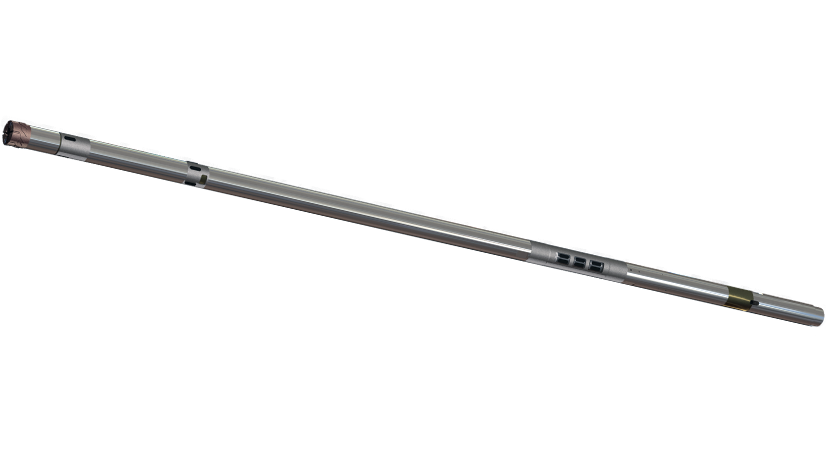

Specifications

Total weight

57kg / 125lbs

Total length

4.5m / 14.5ft

Bit diameter

NWL

Reamer diameter

NWL

Tool body diameter

72mm / 2.83"

Hole diameter

75.7mm / 3"

Core diameter

31.5mm / 1.24"

Core length

3m / 10ft

Instrument barrel length

20cm / 8"

Instrument barrel diameter

51mm / 2.01"

Pumping/latching unit

Longyear NQ™?

Landing ring

Longyear NQ™?

Landing indication

Yes

Core block indication

Yes

Pull out by-pass valve

Yes

Uses of additives

Optional

Typical dogleg severity (DLS)

5-9°, 30m / 5-9°, 100ft

Operating flow

30-50l/min / 8-13gal/min

Operating pressure

20bar + circulation pressure

Feeding force (max)

4500kg / 9900lbs

RPM

300-1200

Recommended parameters

Dogleg severity, NWL rods

9° pr. 30m / 9° pr. 100ft (180m/590ft radius)

RPM

300-800

Feeding force (Bit weight + sliding force)

1500-2500kg

Typical penetration rate

3m/h / 10ft/h

Typical production rate

9 - 27m/12h / 30 - 90ft/12h (50% - 75% of conventional wireline drilling)

Product support, anywhere, anytime

We’re committed to offering the highest level of support to our customers, which is why we have launched our Customer Care Portal, so you can receive support on our products and solutions, wherever you are in the world.

- Raise product support requests anytime (24/7)

- Access our comprehensive knowledge base

- Track and manage your support requests

Frequently asked questions

Do we require additional mud pumps, drill strings or other equipment to use the DeviDrill?

No, the DeviDrill fits directly on the standard drill string and operates with similar flow rates as the regular N-sized wireline core barrels. During drilling the DeviDrill is rotated by the drill string at normal speed, typically 7-900 RPM, while at the same time steering the hole in a predefined direction and collecting core samples.

How sharply can the drillhole be turned when utilising the DeviDrill?

We recommend an average turn of 9° per 30m drilled, or a radius of about 200 meters, to make the directional drilling efficient while avoiding excessive wear on the drill string.

How much savings can be expected from using DeviDrill?

Savings can come in many forms, including reduction in drilling metres leading to direct time & cost savings and indirect cost savings due to reduced core handling and logging, fewer drill sites leading to cost & environmental savings, and consistent target accuracy leading to cost savings. If you have a project where you believe directional coring could be used, we recommend contacting us. We prepare directional proposals at no cost, making it easy to see the benefit of DCD in your specific case.

.png)

.png)

.png)

.png)

-Product-Tag-Variant.png)

.png)