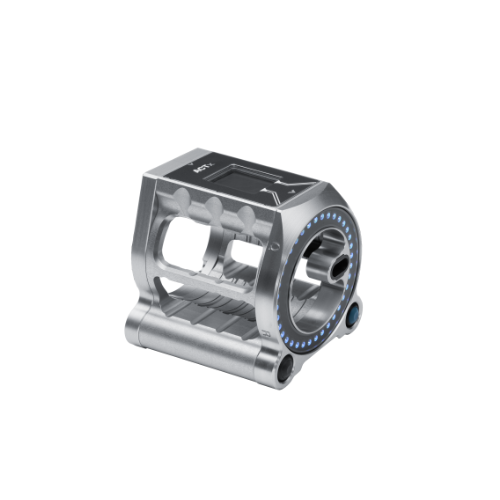

Increase productivity & save rig time when you survey whilst pulling core

Survey at high speeds in continuous and multi-shot nodes

Seeks true north with no risk of magnetic interference

Less manual handling with light weight and Bluetooth

Advanced QAQC results immediately after downloading surveys

IMDEXHUB-IQ™ Integration

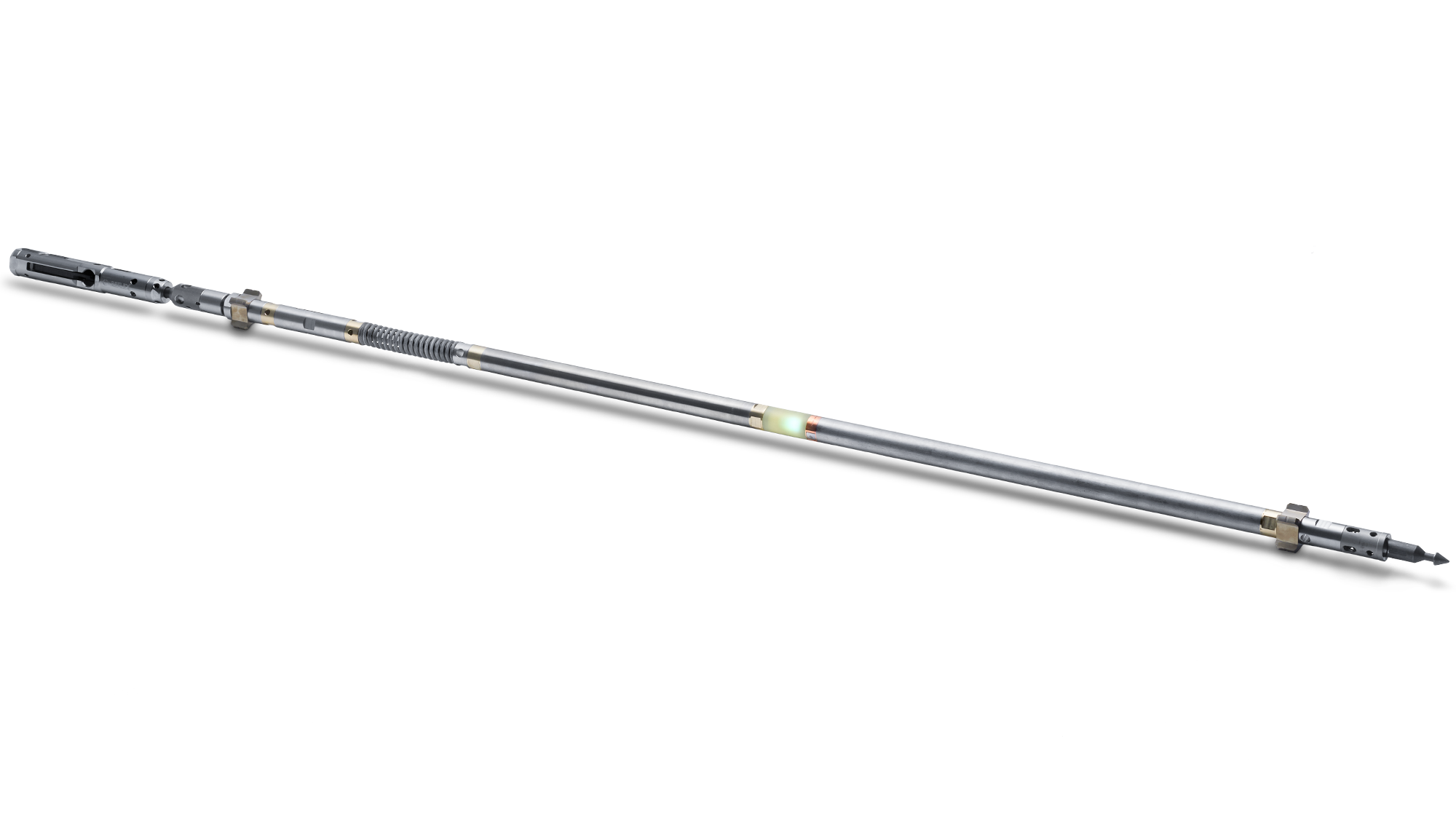

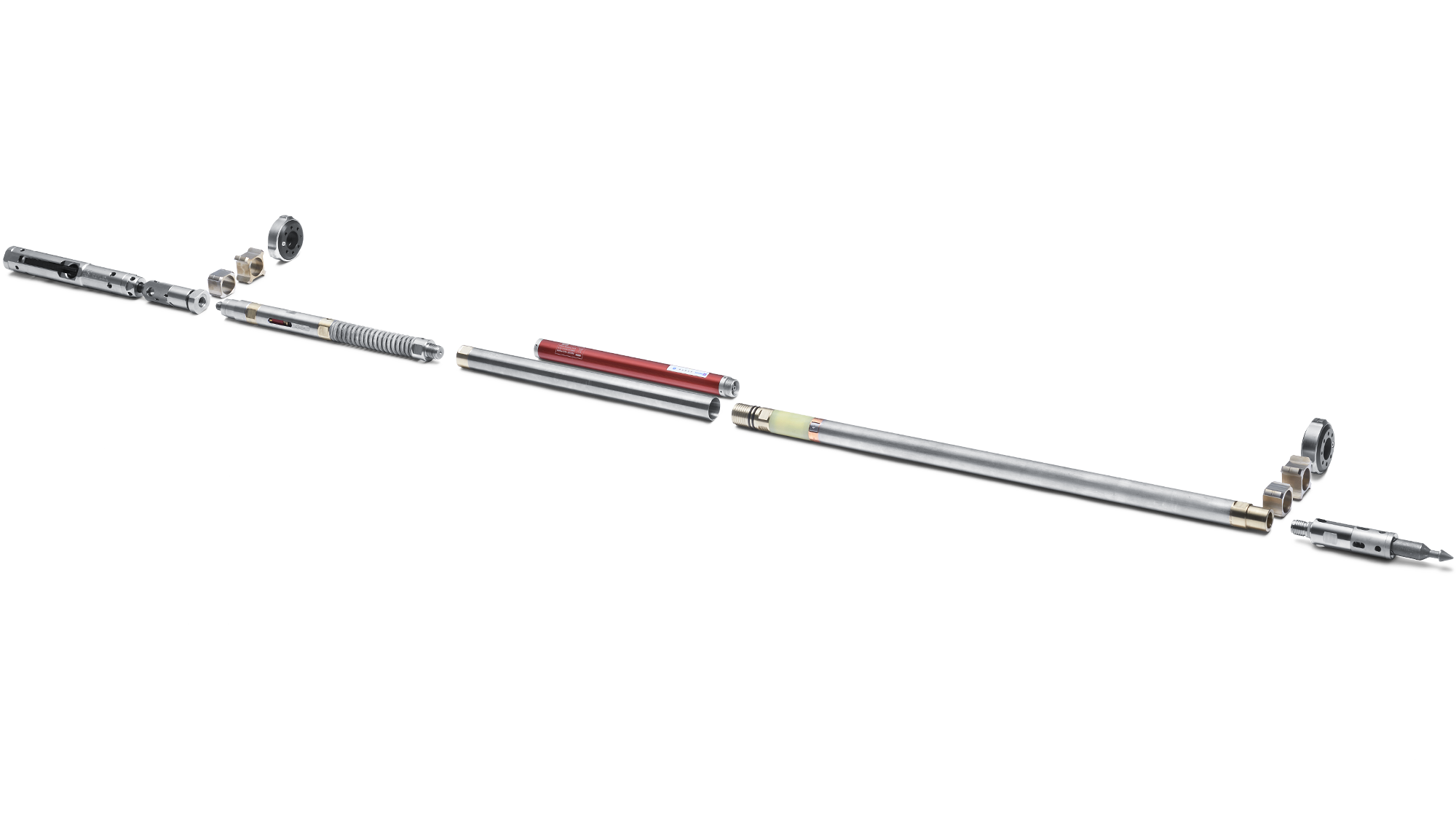

Dimensions

Outer diameter

42.5mm

Length (inc. battery*)

1400mm

Weight (inc. battery*)

8kg

Operational environment

Operational temperature

0° to +70°C (32°F to +158°F)

Depth

4000psi

Shock

500g (inc. bump sub)

Performance

Azimuth**

±0.4° (at 0° latitude)

Dip

±0.25°

Data

CSV export

Survey time

Up to 100m/minute

Survey modes

Singleshot & Multi-shot NS (±30° to ±90° dip)

Continuous NS (±30° to ±80° dip)

Continuous Manual Ref.*** (±30° to ±30° dip)

Battery

Type

Ni-MH rechargeable batteries

Operating time

15 hours each

Field chargeable

Yes, 2 batteries supplied per kit

Data

Quantity

11 hours continuous survey data

Export

USB and WIFI

Format

CSV

*Excluding running gear

**Results depend on latitude and inclination. Accuracy quoted at 1σ and -70deg dip

***Using rig alignment device for starting reference

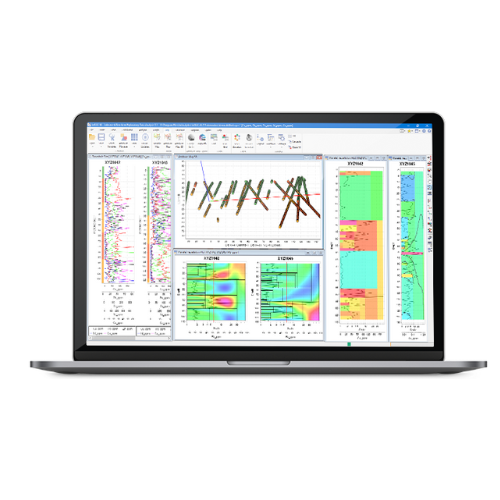

Control multiple IMDEX survey tools through one app.

Less wire, less charges, less equipment

Using one tablet and interface with multiple tools at the same time reduces hardware costs (including tablets, and chargers) while increasing functionality. You can now monitor everything from the one app.

Boost productivity

IMDEX SURVEY-IQ™ has crossed the threshold in saving hours for drilling operations by increasing productivity up to four times compared to using conventional apps.

Multi tool, multi stream, real-time information

IMDEX SURVEY-IQ™ allows efficient and simultaneous quality assured survey and gamma logging that can be completed by one member of the drill crew. Survey results are immediately available for approval via the cloud-based service IMDEXHUB-IQ™. As well as further analysis in ioGAS™ or 3D visualisation software such as Seequent Central

Time stamped drillers run sheet

With paperless run sheets, the driller or supervisor has the ability to work out how many meters per shift, when the drilling happened, and even if there were stops or delays.

Measure depth accurately, quickly and safely.

The REFLEX DEPTH ENCODER™, with its ergonomic design and safety features, reduces the risk of operator injuries while still delivering an easy to assemble user-friendly system.

The unique design maintains its high level of accuracy by reducing the impact of curvature error and making perfect alignment less critical over a wider variety of applications.

The unique design enables the DEPTH ENCODER to work in all standard diamond sizes as well as RC up to 4 ½” and horizontal drilling.

Product support, anywhere, anytime

We’re committed to offering the highest level of support to our customers, which is why we have launched our Customer Care Portal, so you can receive support on our products and solutions, wherever you are in the world.

- Raise product support requests anytime (24/7)

- Access our comprehensive knowledge base

- Track and manage your support requests

.png)

.png)

.png)

.png)

-Product-Tag-Variant.png)