- This helps geologists determine confidence ratings for drill runs where the orientation lines do not match, enabling more confident and informed decisions resulting in enhanced drill program management and geotechnical planning.

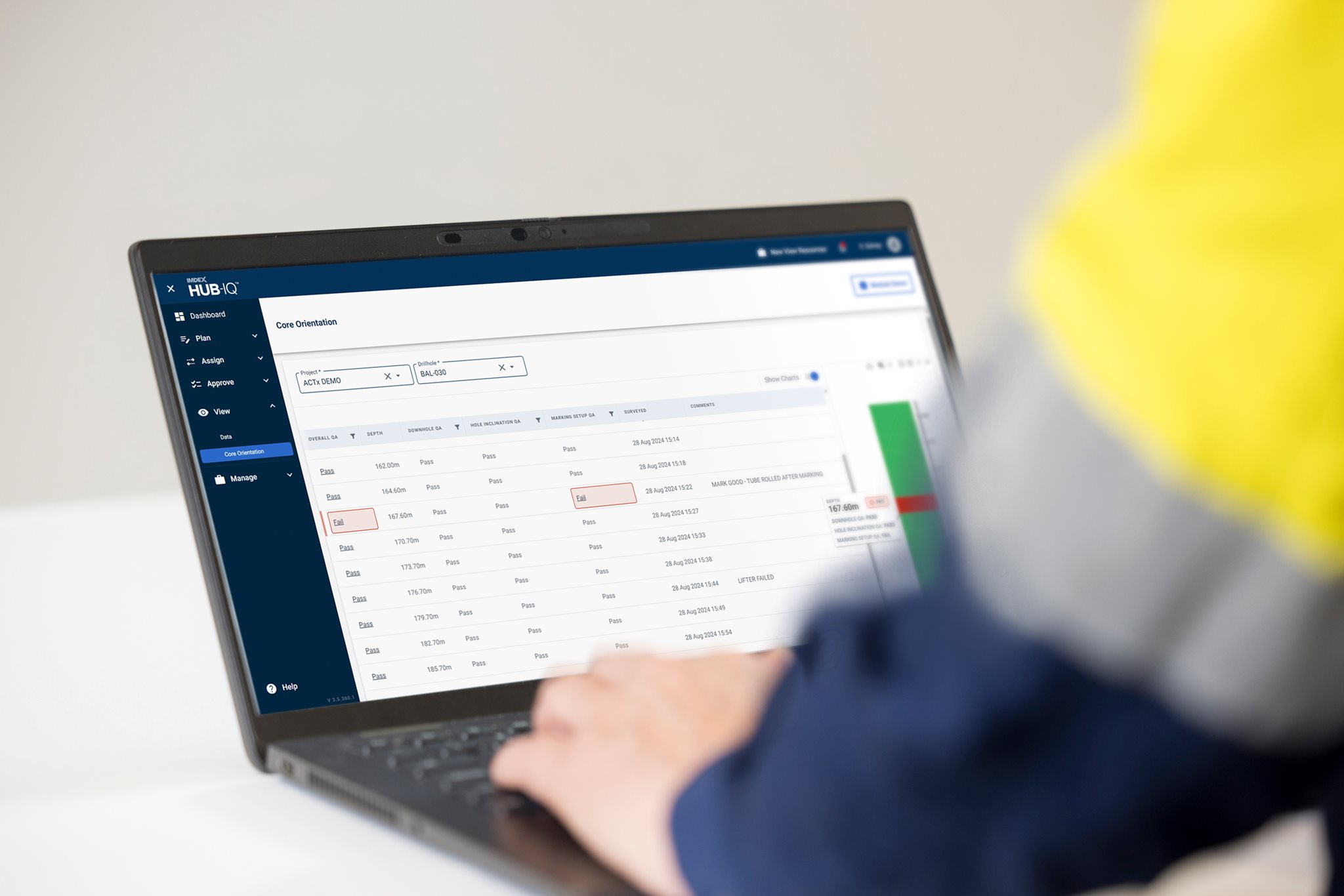

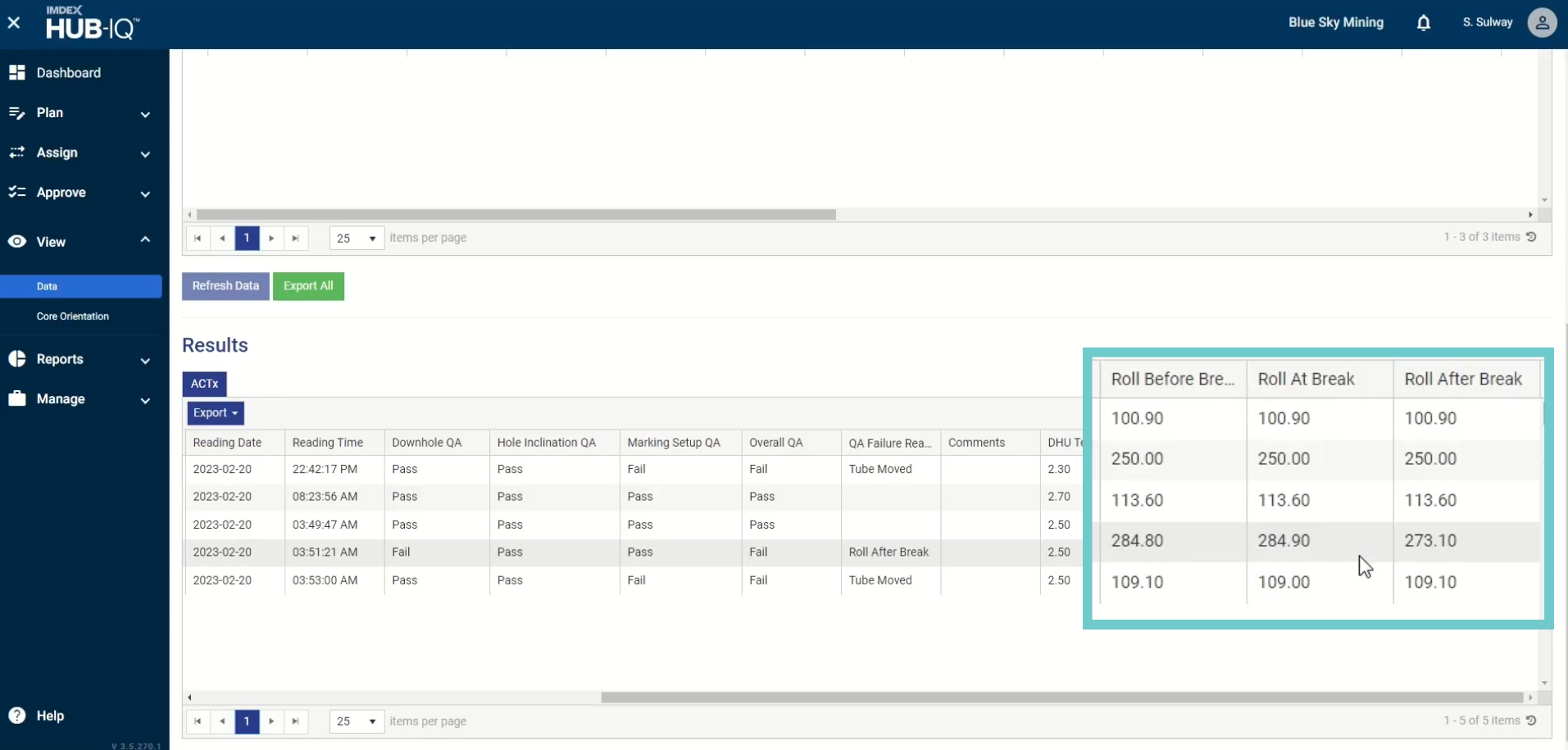

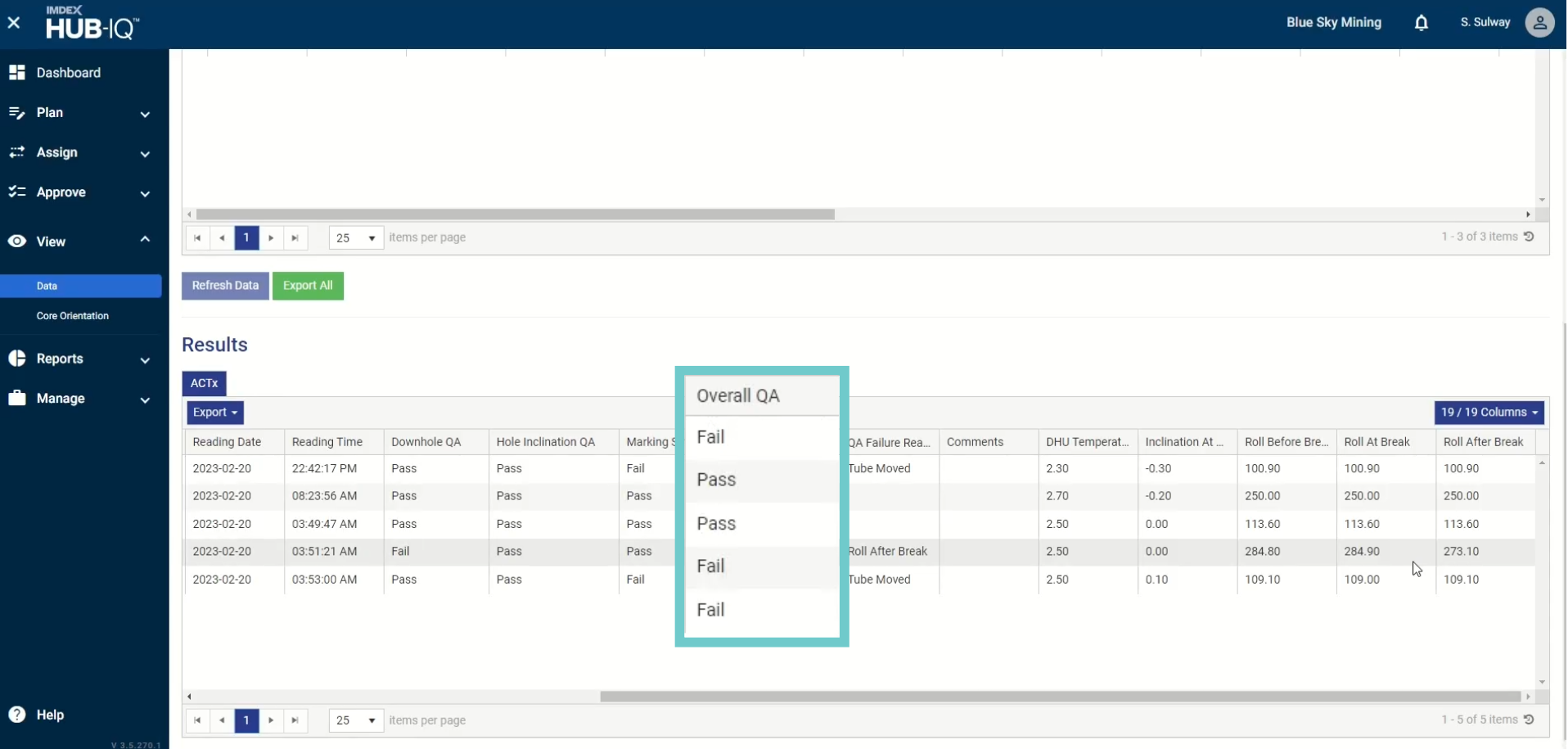

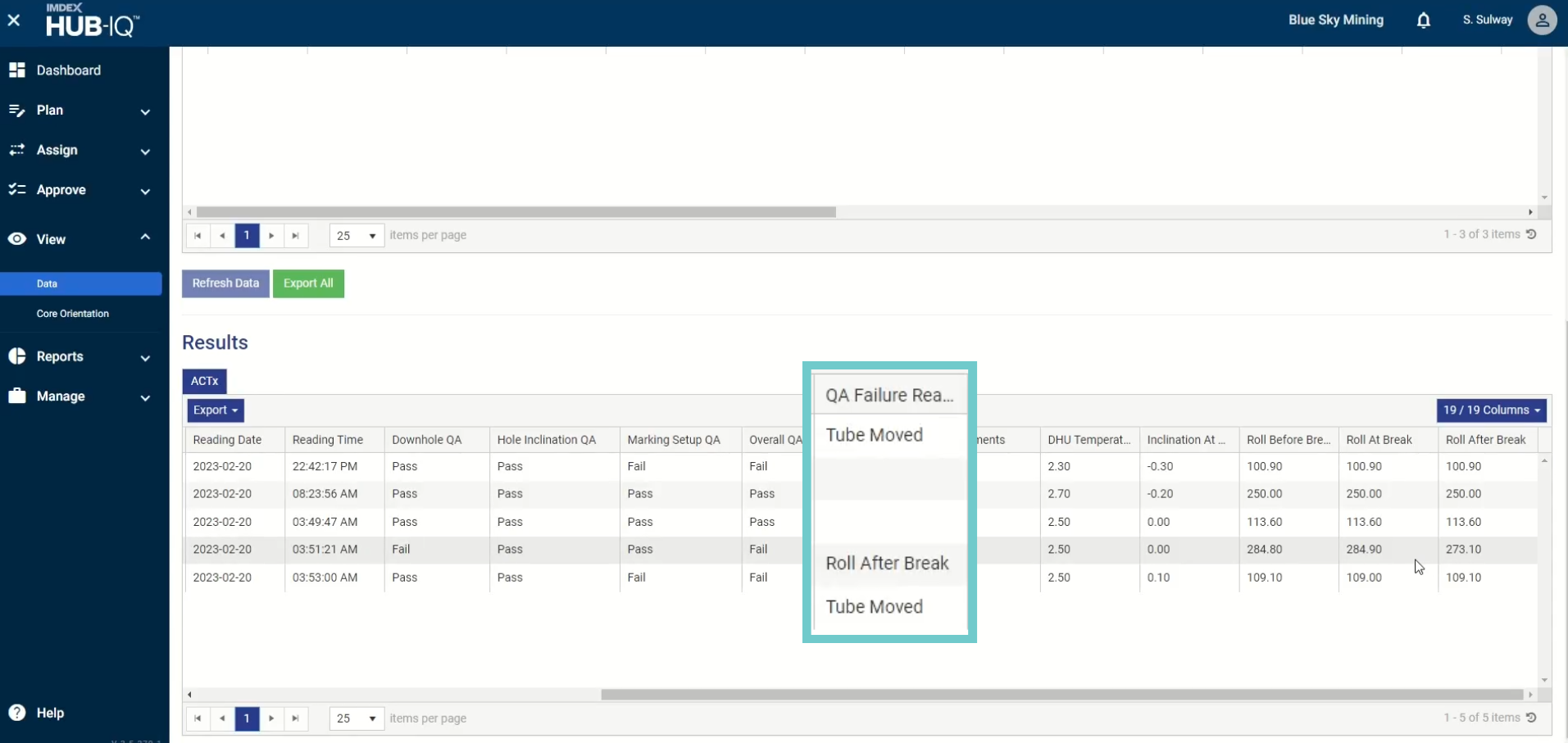

- There are multiple quality assurance flags collected during the core orientation workflow.

- These are then grouped into categories and visible on the Data and Core Orientation views in HUB-IQ:

Downhole QA

Captured: At the moment the orientation reading is taken.

Description and pass criteria: Detects if the drill string is vibrating or the barrel is still rotating in which case the orientation reading will not be reliable.

A pass is recorded in the downhole QA field if the drill string was stable.

A fail is recorded if the drill string was moving as the reading is not reliable.

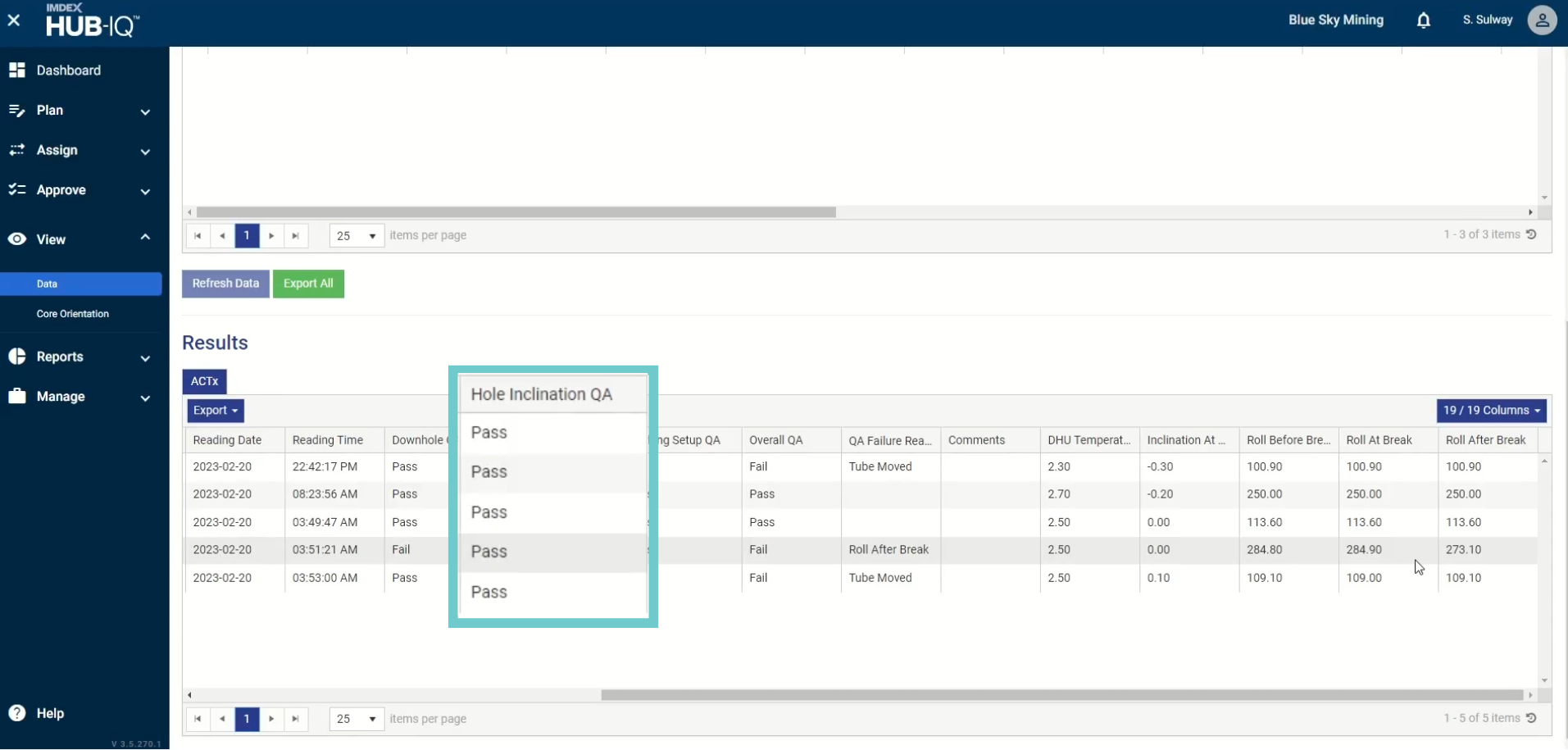

Hole Inclination QA

Captured: At the moment the orientation reading is taken.

Description and pass criteria: In addition to taking the orientation reading, the sensor also determines the dip at the time the orientation reading was taken.

A fail is recorded when the dip approaches 90° as this indicates that the dip is excessively steep for a reliable determination of bottom of core.

A warning is recorded if the change in depth between two successive drill runs exceeds 5°.

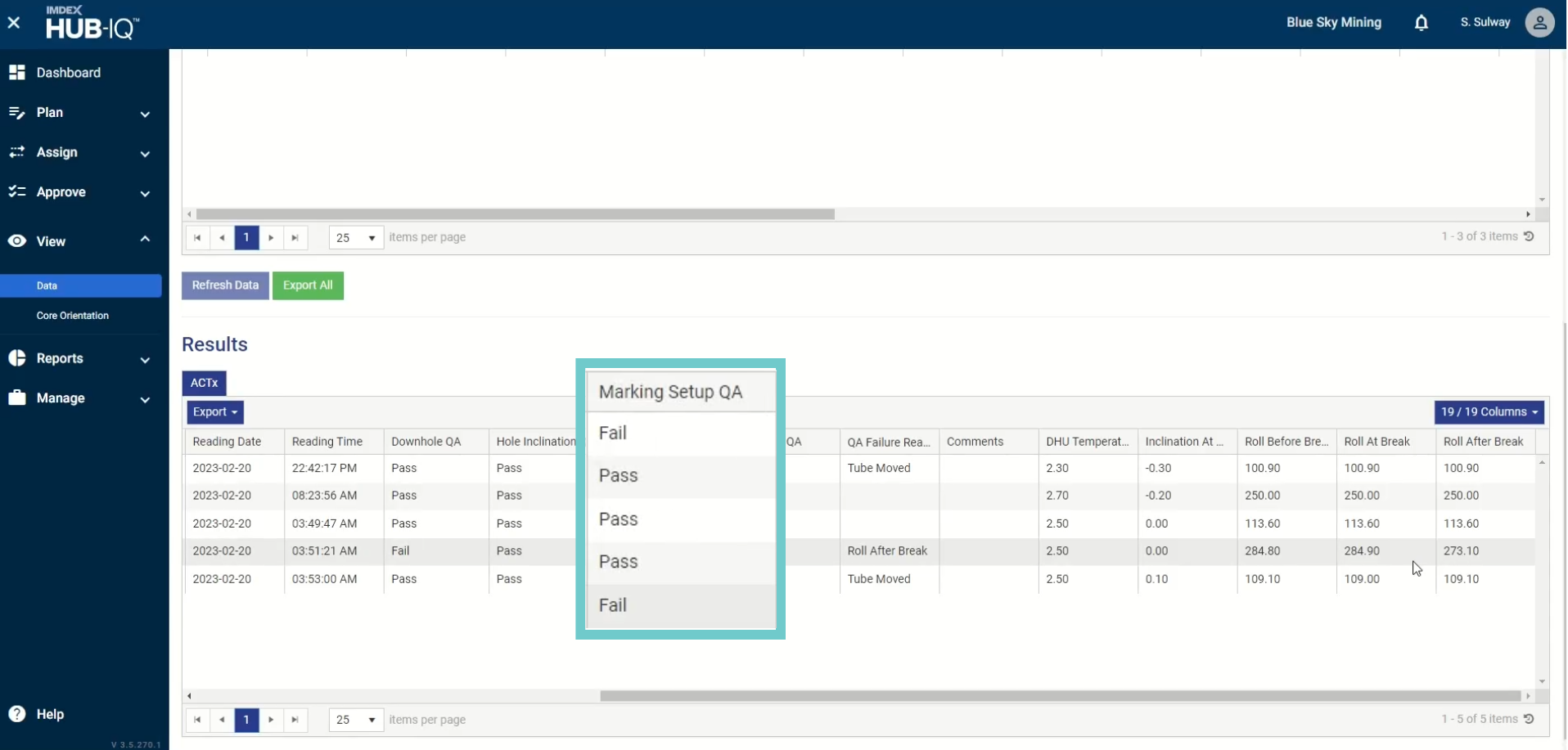

Marking Setup QA

Description and pass criteria:

The marking setup QA relate to errors that can occur during the workflow associated with marking the core.

If the tube has moved between when the orientation is recorded and the final QA step, then the location of the mark may be inaccurate.

The operator does have the option to redo the mark step if the final QA fails.

If the tube is placed on racks at an excessively inclined angle, the accuracy of the sensor may be affected. If this is the case, then this field will be flagged with a warning.

Overall QA

Description and pass criteria: The overall QA field will display the most severe results of the three QA flags. This field will be blank if the orientation was skipped.

QA Failure Reason

Description and pass criteria: In addition to the QA fields, there is also a field called QA Failure Reason which lists all the QA issues recorded as well as if any workflow steps were skipped.

Inclination at break | Tool was approaching vertical at the time of the break, which could potentially result in an unreliable reading |

No read | No mark | The read and no mark indicate either the read or mark step were skipped |

QA skip | Indicates that the QA step to determine if the tube rolled was skipped |

Inclination between breaks | The inclination between successive drill runs is >5° |

This facilitates better communication between drillers and geologists.

Keeping a detailed record of orientation data for each drill run provides a valuable historical reference, that can be invaluable when revisiting and re-evaluating projects.

This secure, auditable data trail delivers automatic capture of quality assurance during the core orientation workflow to ensure that every orientation is validated, reducing errors and strengthening customer relationships between drilling contractors and resource company.

.png)

.png)

.png)

.png)