Case Study

DeviGyro OX Mini improves workflow efficiencies with reduced cost and safety benefits

Location: Limpopo, South Africa

Resource Company: Leading platinum producer

Drilling Contractor: Hall Core Drilling

Project: Underground drilling campaign for resource expansion

Resource: Platinum

The Challenge

The drilling contractor used a single survey tool across five drilling rigs to minimise costs for underground surveys. This resulted in frequent transportation of the tool between drill rigs, causing operational and cost inefficiences.

Increased manual handling also posed potential safety risks, especially in an underground environment.

IMDEX Solution

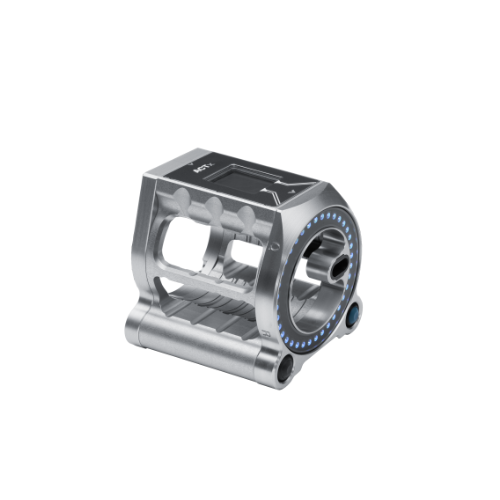

DeviGyro OX Mini

The DeviGyro OX Mini is an ultra compact survey solution that combines the minature reference DeviGyro sensor with OverShot Xpress running gear suitable for BQ and NQ surveying.

Completely wireless and safe to be handled by one operator, the OX Mini is pre-assembled in one case, making it the ultimate solution for underground diamond drilling.

Strategy

IMDEX introduced 5x DeviGyro OX MINI reference gyro systems - one for each rig. Key advantages included:

- Seamless integration

OX MINI systems are permanently fixed on the drill’s overshot, eliminating the need for transporting survey tools between rigs.

Improved workflow

Accurate, continuous surveys (10 data points/sec) can be conducted at the end of each drill run, and data is synced frequently for near real-time borehole monitoring.

Compact design and enhanced safety

OX MINI is 3.2x lighter than the original surveying tool, reducing space constraints and manual handling risks. Bluetooth connectivity and magnetic activation removes the need for cables and manual tool joint breaks, lowering the risk of injuries.

.png)

.png)

.png)

.png)