Case Study

DeviDrill™ delivers directional drilling program of high technical quality in environmentally sensitive area

Resource Company: Anglo American

Project: Sakatti

Resource: Cu-Ni-PGE

Application: Metallurgical drill program

Season: 2022-2023 Winter season

Objectives

Collect the metallurgical samples from the Sakatti Cu-Ni-PGE deposit by means of core drilling.

Maintain a constant 25m drilling pattern in certain key areas of the deposit with the required 5m target precision (up to 800m depth).

Adhere to project time and environmental constraints.

Challenges

The Sakatti copper, nickel and PGE deposit in Finland (150km from the Arctic Circle) is a deep and complex deposit located in an environmentally sensitive area.

Drilling operations can only be conducted in winter on frozen and snow-covered ground, effectively limiting available drilling time to 4 months a year.

For a successful program it is therefore crucial that each target is reached with the highest possible efficiency and accuracy whilst minimising surface disturbance.

IMDEX Solution

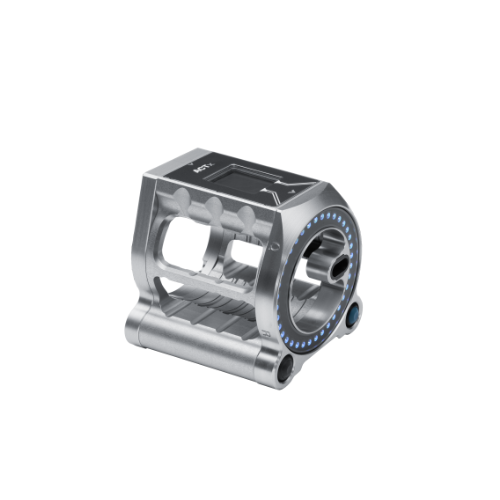

Devico DeviDrill Directional Core Drilling (DCD) services.

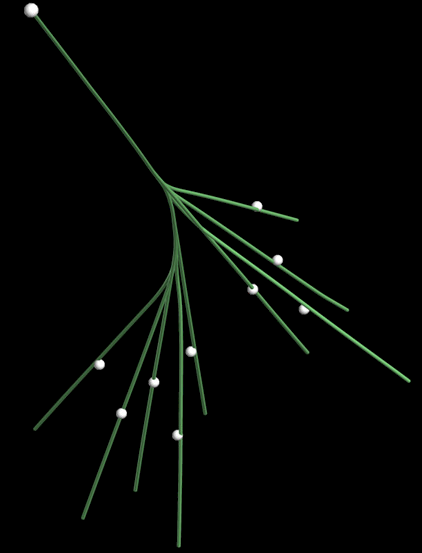

The DeviDrill is an innovative directional core barrel that delivers highly accurate borehole steering whilst collecting a 3m/10ft core sample, leading to the application name, Directional Core Drilling (DCD).

Strategy & Solution

Several multi-branch DCD holes were planned by Devico in consultation with Anglo American's Sakatti project geology department.

Devico crews cooperated with the drilling contractor to carry out the required directional drilling, supervising and adjusting the borehole paths to ensure tolerances were maintained.

The length of the corrections varied from 5 to 75 metres and were planned with a dogleg (deflection rate) of 9 degrees per 30 metres.

On average, each directional intervention lasted two days or less, with multiple 12-hour shifts recording over 20 metres of directional drilling.

.png)

.png)

.png)

.png)