Case Study

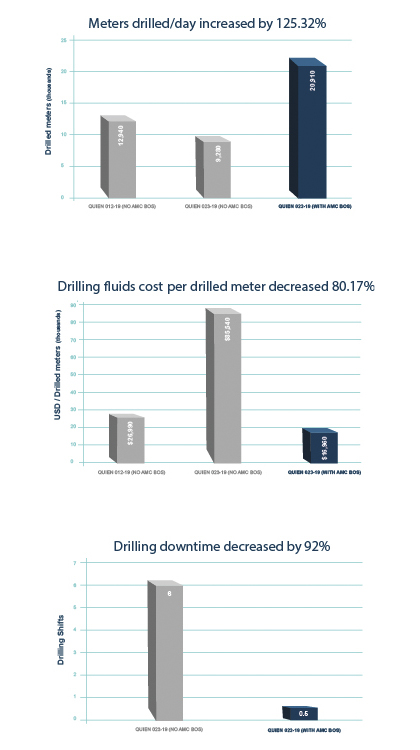

AMC BOS™ maximises productivity, improves borehole stability, and reduced drilling fluids costs

Location: Peru

Resource Company: AK Drilling International

Project: Quenamari Project

Objectives

Maximising productive hours and ensuring borehole stability. Whilst also improving drilling conditions, and reducing drilling mud costs.

Challenges

Drilling mud circulation losses with low rates of penetration (ROP).

Borehole obstructions caused by mechanically unstable formations.

High amount of hours spent in ground conditioning and redrilling borehole obstructions.

High consumption of water and drilling additives.

Wear and tear of drilling tools, increasing nonproductive time spent on frequent rod trips.

IMDEX Solution

lMDEX and AK Drilling International teamed up to find the most proper and efficient solution to the recurrent problems at Quenamari project. The joint and articulated action of a properly formulated drilling fluid and the periodic use of AMC BOS equipment was proposed.

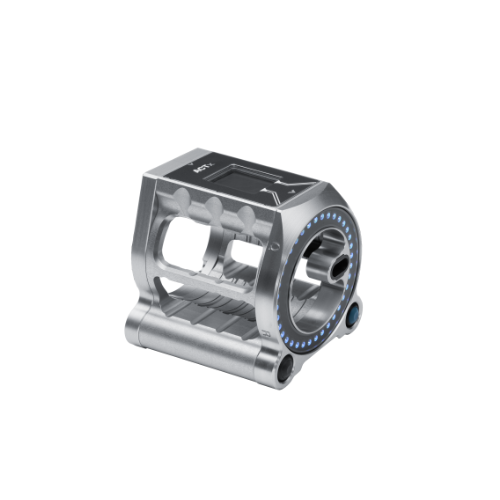

BOS is a proactive solution combating fluid losses and borehole instability, by delivering a measured amount of AMC BOS FIX at regular intervals to the bottom of the drill string and up the annulus. The fluid reacts instantly with borehole fluids, permeating and sealing fractures, providing a thin but robust lubristic membrane to the borehole wall.

Strategy & Solution

The BOS is comprised of a driller-operable, casing-while-drilling tool, the AMC BOS UNIT™; and lubricating rapid-fill polymer grout, the AMC BOS FIX™.

BOS is a proactive solution combating fluid losses and borehole instability, by delivering a measured amount of AMC BOS FIX at regular intervals to the bottom of the drill string and up the annulus. The fluid reacts instantly with borehole fluids, permeating and sealing fractures, providing a thin but robust lubristic membrane to the borehole wall.

.png)

.png)

.png)

.png)