Case Study

AMC BHS™ reduces re-drill rate by 58.5%

Location: Chile

Resource: Copper

Application: Integral optimisation of the drill & blast process

Challenges and objectives

The client wanted to decrease the re-drill rate whilst adhering to their drill design, and had various KPIs they needed to achieve:

• Reduction of re-drill by at least 50%.

• Increase performance of drilling rigs by increasing tricone penetration rate.

• Improve explosive charge by drilling closer to the design.

They needed to maintain a safe operating environment, therefore ensuring a low level of particulate matter was also important.

IMDEX Solution

BORE HOLE STABILISER (BHS)

Drilling fluid specifically formulated for use in production drilling rigs. The application complements the use of a mixing unit which guarantees the homogeneity of the stabilising solution that is directly deposited in the water tanks of the drilling rigs.

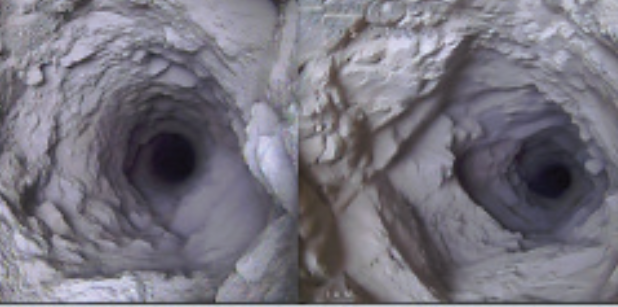

It helps prevent a wide range of down-hole problems including poor collaring, hole decay or sidewall instability.

BHS has a unique formulation which enables it to penetrate deep into the surrounding strata where it will bond friable, fragmented materials, significantly reducing the need for excess conditioning, expensive re-drills or casing.

Strategy & Solution

In partnership with the client over three months, IMDEX implemented BHS at their sites. IMDEX provided technical assistance in the field and a combination of classroom & practical field training sessions. IMDEX technicians also provided analysis of results throughout the trial period.

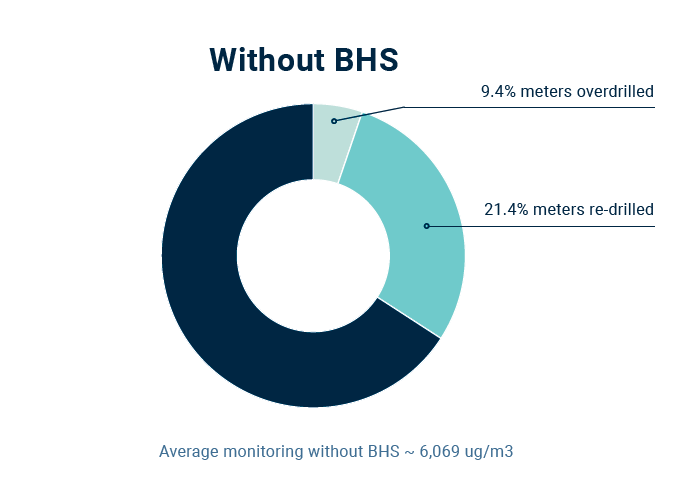

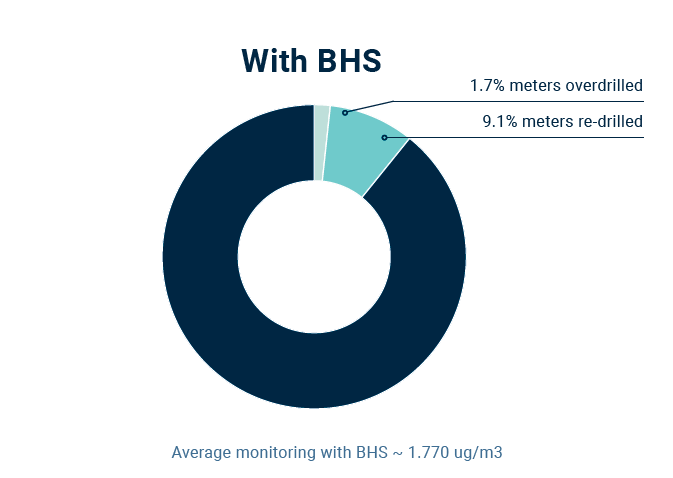

During this time they drilled 10,114 meters, 3,762m dosed with BHS, finding that dosing holes with BHS decreased the rate of re-drilling by 58.5% and reduced overdrilling by 81.9%.

Another key performance indicator for the client was to quantify the benefits in terms of dust suppression during the drilling process.

From approximately 5,000 samples, operational dust suppression was reduced by 71%* when using BHS compared to the established baseline.

The suppression of respirable particulate matter using BHS was closely monitored during the process, quantifying a 93% improvement by decreasing the exposure level of operators.

Explosive loading

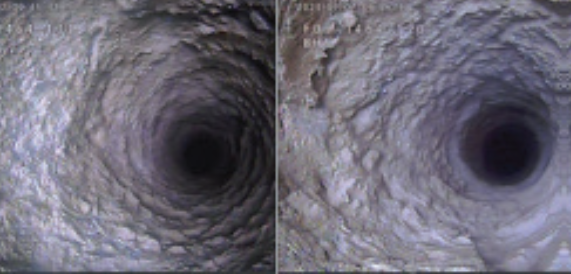

BHS helps the evacuation of cuttings from the bottom of the blasthole, improving the interaction of the drilling steel with the rock mass.

BHS also reduces the crumbling and maintains the internal volume of the blasthole, allowing better adherence of the drilling cylinder. This ultimately optimises the actual explosive charge per blasthole, which resulted in 3% closer explosive loading compared to the planned theoretical value.

.png)

.png)

.png)

.png)