The scale of the opportunity to deliver real value was clear: a drilling error of just 1° can shift a 30m (98 ft) long hole by half a metre (1.64 ft) at the toe. That small deviation can distort burdens, misalign slots, and compromise wall control. The consequences and costs are significant:

• Dilution and/or ore loss;

• Hang-ups and secondary blasting;

• Unplanned overbreak and fill overruns;

• Safety risks from breakthrough into fill or adjacent voids

Resource companies knew they were leaving ore behind, but the manual, resource- and time-intensive methods of measuring deviation simply outweighed the incentive to make it work. The relentless pressure of tight firing windows and aggressive production targets often meant that, even when surveying was conducted, it was typically performed by contractors on an inconsistent basis or reserved only for mission-critical stopes. In many cases, the process became a box-ticking exercise, and what happened to the data afterwards was anyone’s guess.

Recognising this gap, IMDEX set out to develop a production hole surveying system that would transform deviation measurement from a burden into a strategic advantage. The solution needed to be faster, more accurate, safer, and seamlessly integrated into production workflows. Most importantly, it had to deliver actionable data to engineers immediately, not days later when the blast had already occurred.

As a result, OMNIx™BOLT was born: a true north-seeking gyro system that wasn’t just adapted but reimagined for the demands of underground production mining.

.jpg)

The system

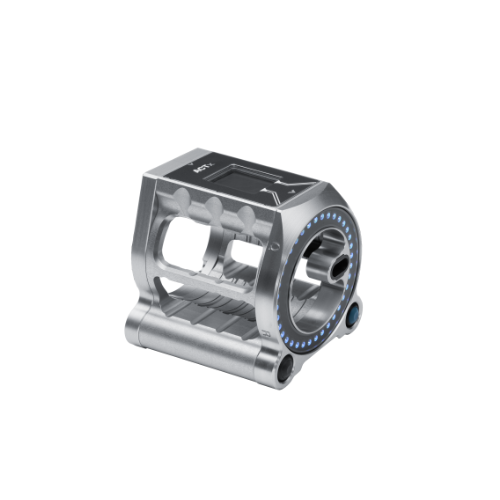

North-seeking gyro

OMNIxBOLT’s gyro delivers continuous, high-accuracy measurement of dip and azimuth, even in challenging underground environments. The probe is lightweight—approx. 5kg (11 lb)—modular, and designed for easy transportation and deployment by two operators.

Custom clip-fast bow spring centralisers ensure in-hole stability and accurate data collection across a wide range of hole diameters—from 64 to 150mm (2.52 to 5.91 in).

Guider

The telescopic OMNIxBOLT guide tube eliminates the need for Elevating Work Platforms (EWPs) or Integrated Tool Carriers (ITs), extending up to 6.5m (21 ft) to reach overhead collars from the ground.

Its lightweight, collapsible design, integrated safety features, and wireless communication window enable safe, efficient, and rapid underground deployment. By removing the requirement for EWPs or ITs, the guider ensures that these critical machines remain available for other essential tasks.

The guider also reduces operational bottlenecks, thus minimising disruption to mine productivity, and adds flexibility to survey campaigns.

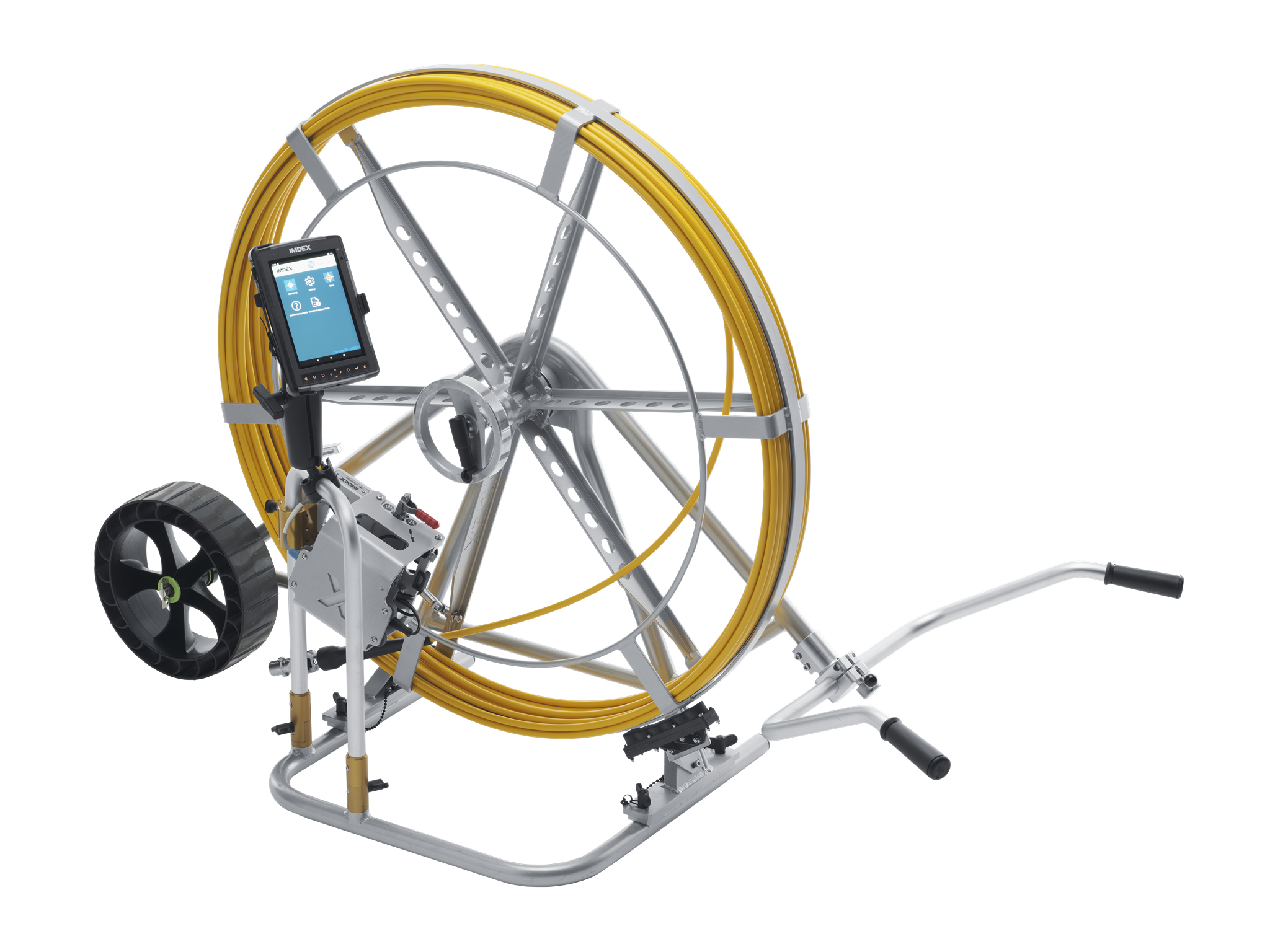

Rodder reel

The robust fiberglass rodder reel enables surveys up to 60m (197 ft), with a digital encoder for precise depth tracking. The system’s modular design allows for quick setup and minimal manual handling, reducing operator fatigue and risk.

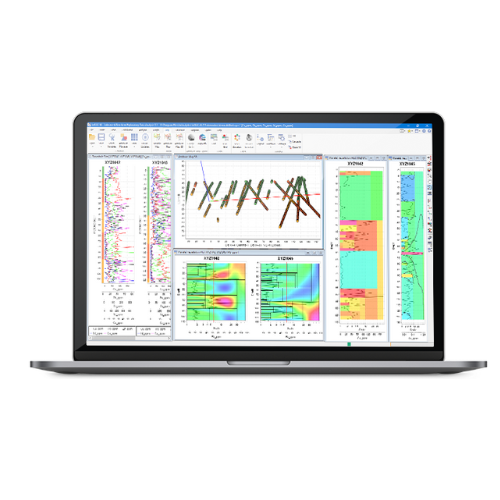

SURVEYx™MINE software

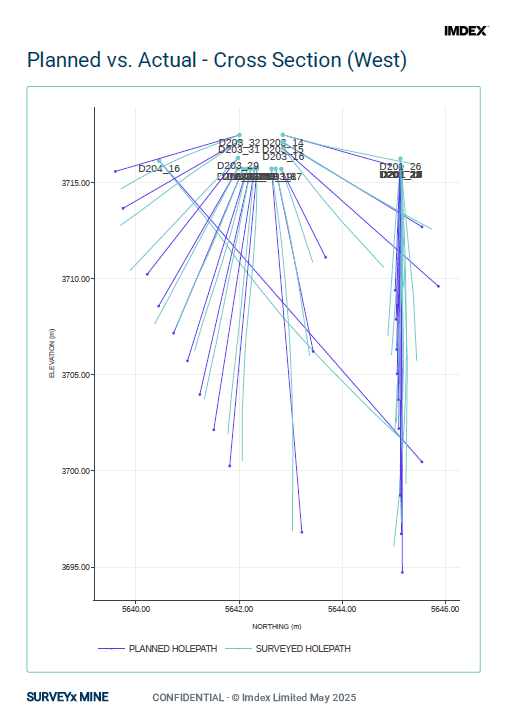

The tablet-based application streamlines the entire workflow, from importing drill plans to exporting survey data in CSV and DXF formats. Real-time QA/QC is built in, with in-run and out-run surveys for every hole, enabling immediate validation and error correction.

A deviation report is generated and includes a summary of survey data, setup errors, in-hole deviation errors, and three sectional views of each drillhole (long section, cross section, and toe alignment). Reports can be collated across campaigns, providing comprehensive insights for mine planning and reconciliation. Reprocessing surveys in the event of a collar relocation is seamless, automatically regenerating all data and deviation reports.

The value

The value of OMNIxBOLT is most directly realised by drill and blast engineers, mine planners, and technical services teams responsible for production hole design, execution, and reconciliation. However, its benefits are readily apparent to decision-makers at every level of the mining operation.

The system shines in high-stakes, high-throughput environments where the cost of poor data or delayed feedback is significant.

Key applications include:

• Slot rises and long hole open stoping: Accurate collar and toe position data is critical for optimal blast design, minimising dilution, and maximising ore recovery.

• Narrow vein operations: Where precision is paramount and the margin for error is slim, OMNIxBOLT’s accuracy and immediate reporting support better decision-making.

• Block cave and sublevel caving: The ability to survey both upholes and downholes, and to do so quickly and safely, supports complex mining sequences and aggressive production targets.

• Critical infrastructure and mission-critical stopes: It enables consistent, campaign-wide surveying, not just spot checks, ensuring that every blast is informed by high-quality data. This approach not only optimises immediate outcomes, but also informs long-term strategies, reducing issues in future plans.

Training and support

IMDEX recognises that technology is only as effective as its users, which is why OMNIxBOLT is supported by comprehensive training programs, delivered onsite or remotely. The intuitive design of the system, combined with detailed training resources and real-time QA/QC feedback, means that operators can quickly become proficient, regardless of prior surveying experience. Ongoing support and remote monitoring further ensure that mines can maintain high standards of data quality and operational safety from day one.

Real results

As with any mining technology, the true value of OMNIxBOLT is best illustrated through its performance in the field. Now deployed across the world and having surveyed over 350km 4500 drill holes (and counting), the results speak for themselves.

At one Australian mine site, OMNIxBOLT is now used to survey every production hole, addressing long-standing challenges with flat slot rises and dilution. Surveys have become a ‘priority one’ requirement for the operation, a shift driven by measurable results: the site is recording an estimated gold recovery increase upwards of USD $8,000,000 per truck annually

At a gold and silver mine in Chile, OMNIxBOLT replaced inaccurate magnetic survey tools and eliminated the need for ITs or EWPs. The system improved operational safety, reduced personnel requirements, and enabled comprehensive on-site data validation. Most notably, OMNIxBOLT reduced drill and blast operating costs by up to USD $600,000 per year and improved dilution by more than 10%, directly contributing to increased production and efficiency.

OMNIxBOLT represents a significant advancement and step change in underground production hole surveying, transforming deviation measurement from a costly, inconsistent afterthought into a strategic driver of safety, efficiency, and ore recovery. By delivering immediate, high-precision data through SURVEYxMINE, engineers and planners gain the clarity needed to make informed decisions before the blast, not after.

The level of insight gained with OMNIxBOLT and its unique reporting format enables operations to not just measure but identify the root causes of toe errors. Teams can now consistently and proactively address or plan for these errors to achieve the highest toe accuracy possible.

As the industry continues to demand more from every tonne, OMNIxBOLT stands out as a solution built for the realities and opportunities of modern mining. With proven results across global sites and mining methods, it’s delivering measurable value from every drill hole.

.png)

.png)

.png)

.png)

.jpg)

_1.png)