Case Study

The workflow transformation that empowered Grasberg Mine with safer, error-free surveying

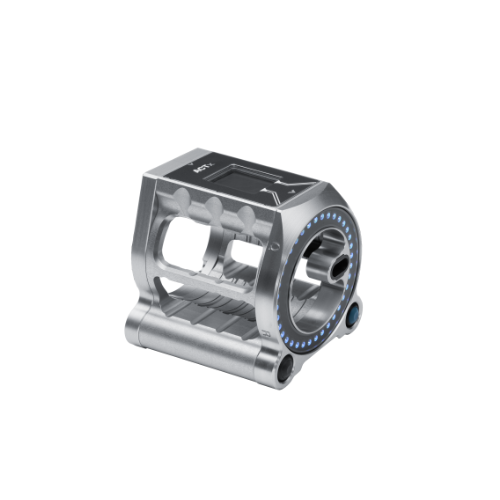

Near real-time downhole analysis, an advanced design and proven reliability deliver consistent, actionable results for Indonesia’s largest gold mine

Location: Indonesia

Resource Company: PT Freeport

Project: Grasberg Mine

Key Benefits

- Lightweight and Safe: Designed for easy handling and operator safety.

- Superior Data Quality: Delivers clear, detailed analysis for confident decision-making.

- Reliable Performance: Over 50,000 metres surveyed and 150 holes completed with zero errors.

- Durable Battery Life: Ensures uninterrupted field operations.

- Seamless Integration: Real-time syncing with HUB-IQ™ for efficient reporting.

The Challenge: Achieving Precision and Reliability in Complex Drilling Conditions

In Central Papua, PT Freeport’s Grasberg Mine faces a familiar challenge: maintaining accuracy and reliability in downhole surveying across diverse drilling scenarios. With drilling angles ranging from uphole, horizontal, vertical, to downhole, the team needed a solution that could deliver consistent, high-quality data without compromising safety or efficiency.

“The types of holes here are diverse. We’ve used the OMNIx38 to measure all of these.”

PT Freeport's perspective: In their own words

Hear directly from Najamudin at PT Freeport as he shares firsthand experiences with OMNIx38, covering everything from daily operations to the responsive support provided by IMDEX.

What OMNIx38 Delivered for PT Freeport

- Consistent, error-free results: No issues during use or data processing.

- Operational versatility: Successfully measured a wide range of hole types.

- Enhanced safety: Lightweight design reduces manual handling risks.

- Improved efficiency: Real-time data syncing and reporting accelerate decision-making.

Partnership and Future Plans

IMDEX’s responsive support both in-person and online has been a key factor in the mine’s success.

“The response is quick, whether through direct visits or online. We hope to continue building a strong relationship between IMDEX and our company.”

The Grasberg team also leverages complementary tools like TN14™ and ACTx™, with plans to adopt DeviAligner™ for even greater alignment accuracy.

“We also use TN14 and ACTx, which have been very helpful. And we hope to start using DeviAligner soon.”

OMNIx38 has become a cornerstone of surveying operations at PT Freeport Indonesia’s Nusa Jaya site. Its reliability, data quality, and seamless integration have significantly improved operational efficiency and decision-making. With ongoing support from IMDEX and a commitment to innovation, the team is well-positioned for future success.

.png)

.png)

.png)

.png)