Case Study

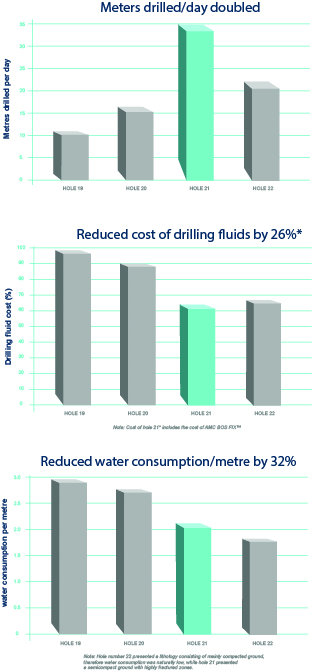

AMC BOS™ doubles metres drilled per day

Location: Chile

Resource: Au

Application: Drill hole efficiency

Objectives

Increasing productivity with improved drillhole stability. Reducing consumption of mud and water due to lost circulation and high torque.

Challenges

Some 3,500 to 5,200 metres above sea level, the site had issues with constant formation changes and complicated fault zones.

Formations consistently produced complete or partial fluid losses. There were several soft and problematic formations resulting in lost circulation and issues such as hole failure, stuck rods, and lost casing.

Such lost circulation problems delayed the drilling program, which, in turn, delayed total progress of the project and its comparative performance against other campaigns in the same area. The client implemented reverse circulation pre-collars before diamond drilling to complete more drillholes; however, they were searching for a preventative solution to address lost circulation.

IMDEX Solution

AMC Borehole Optimisation System™ (BOS)

The BOS solution includes the AMC BOS UNIT™ a driller-operable in-hole lubricating and casing while drilling tool, and AMC BOS FIX™, a rapid-fill polymer grout.

After an initial trial, AMC BOS had achieved strong results. For the second trial, it was suggested the method be implemented from the commencement of the hole as a preventative measure against lost circulation.

Strategy & Solution

Throughout the trial at hole 21*, BOS FIX was injected at regular intervals, penetrating fractures and securing unstable rock by encasing the borehole wall with a thin, lubricating membrane. AMC BOS was able to treat the application area, which consisted of semi-compact rock with fractured zones to improve stability, torque control and fluid losses from beginning to end.

Comparing results from similar holes 19, 20, 21 and 22* - holes which were drilled using Reverse Circulation (RC) pre holes and continued with Diamond Drilling (DOH). At hole 21* AMC BOS maintained a lubristic membrane down the borehole allowing for safe, constant and controlled drilling.

From the implementation of the BOS, several improvements in drilling efficiency were achieved, and all were pleased with the overall result.

*Compared to holes with similar characteristics (19, 20, and 22). Numbering of the holes has been modified for confidentiality.

.png)

.png)

.png)

.png)